- Home Page

- Company Profile

-

Our Products

- Block Making Machine

- Coir Pith Block Making Machines

- Autofeeder Hollow Blocks Making Machines

- Hand Operated Block Making Machines

- Cover Block Making Machine

- Hollow Block Making Machine

- Interlocking Paver Block Vibrating Table

- Solid Double Hollow Block Making Machine

- Hydraulic Paver Block Making Machine

- Heavy Duty Cement Block Making Machine

- Heavy Duty Hollow Block Making Machine

- Triple Vibrator Concrete Block Making Machine

- Double Punch Solid Block Making Machine

- Hydraulic Hollow Block Making Machine

- Semi Automatic Concrete Blocks Making Machines

- Triple Vibrator Hollow Block Making Machine

- Hydraulic Concrete Block Making Machine

- Stationary Automatic Concrete Block Making Machine

- Auto Feeder Block Making Machine

- Automatic concrete blocks making machines

- Everon Industries Heavy Duty Paving Blocks Machine

- Heavy Duty Block Making Machine

- Paver Block Making Machine

- Heavy Duty Concrete Block Making Machine

- Hydraulic Operated Paving Block Making Machine

- Solid Block Making Machine

- Concrete Cover Block Making Machine

- Designer Paver Machine

- Egg Laying Concrete Block Making Machine

- Interlocking Soil Block Making Machine

- Heavy Duty Solid Blocks Making Machines

- Stationary Concrete Block Making Machine

- Manual Block Making Machines

- HYDRAULIC CEMENT BLOCK MAKING MACHINE

- EGG Laying Solid Block Making Machine

- Heavy Duty Automatic Concrete Block Making Machine

- Hydraulic Solid Block Making Machine

- Heavy Duty Solid Block Making Machine

- Everon Impex Vibrating Block Making Machine

- Solid Double Hollow Block Machine

- Cement Brick Making Machine

- Everon Impex Heavy Duty Triple Vibrator Block Making Machine

- Cement Block Making Machine

- Automatic Block Making Machine

- Concrete Block Machine

- Hollow Block Machine

- Everon Impex Heavy Duty Bricks Making Machine

- Hydraulic Block Making Machine

- Interlocking Block Making Machine

- Semi Automatic Concrete Hollow Block Making Machine

- HYDRAULIC CONCRETE BLOCK MAKING MACHINE

- Stationery Type Automatic Hollow Block Machine

- Everon Impex Hydraulic Paver Block Making Machine

- Block Making Machines

- Hydraulic Operated Block Making Machine

- Vibro Paver Block Machine

- Everon Impex Vibration Paving Blocks Machine

- Everon Impex Paver Block Making Machine

- Manual Concrete Block Making Machine

- Hydraulic Interlock Machine for Construction Industry

- Everon Impex Heavy Duty Hollow Block Making Machine

- Concrete Solid Block Making Machine

- Egg Laying Block Making Machines

- Cover Block Making Machine And Paving Blocks Making Machine

- Bricks Making Machine

- MUD BRICK MAKING MACHINE

- Fly Ash Brick Making Machine

- Automatic Cement Bricks Making Machines

- Hollow Brick Machine

- Semi Automatic Bricks Making Machine

- Cement Bricks Making Machine

- Semi Automatic Fly Ash Brick Making Machine

- Fully Automatic Fly Ash Brick Making Machine

- Brick Manufacturing Machine

- Concrete Brick Making Machine

- Everon Single Phase Solid Bricks Making Machine

- Hollow Bricks Machine

- Mechanical Type Fly Ash Brick Making Machine

- Semi Automatic Solid Block Making Machine

- Hydraulic Pressure Solid Block Making Machine

- 876 Triple Vibrator Concrete Block Making Machine

- Heavy Duty Solid Bricks Making Machine

- Semi Automatic Fly Ash Bricks Making Machine

- Automatic Fly Ash Brick Plant

- Automatic Fly Ash Brick Making Machine

- Everon Impex Hydraulic Brick Making Machine

- Everon Impex Automatic Bricks Making Machine

- Everon Impex Cement Brick Making Machine

- FLY ASH BRICK

- Concrete Mixer

- Concrete Mixer With Hopper

- Wheel Type Concrete Mixer

- Hydraulic Hopper Door Open Pan Mixer Machine

- Mixer Muller Machine

- Stand Type Concrete Mixer

- Hydraulic Concrete Mixer Machine

- Reversible Concrete Mixer Machine

- Hydraulic Hopper Type Concrete Mixer

- Face Mixer Muller

- Cement Concrete Mixer Machine

- Mobile Concrete Mixer

- Electric Cement Concrete Mixer

- Semi Automatic Non Hopper CI Model Concrete Mixer

- Concrete Mixer Wheel Type

- Cement Mixers

- Concrete Mixer Stand Type

- Vibrator Table

- Pan Mixer

- Earth Rammer

- Paver Cutter

- Vibrator Cum Manual Machine

- Wheel Barrows

- Block Cutting Machinery

- Paver Machine

- Hydraulic Pallet Truck

- Tiles Making Machine

- Everon Industries Parking Tiles Making Machine

- Foot Path Tiles Making Machine

- Vibro Forming Paver Tiles Making Machine

- Vibro Designer Tiles Making Machine for Engineering Industry

- Paving Blocks Making Machine

- Designer Pavers Machine

- Rubber Tile Making Machine

- Paver Designer Tiles Vibro Forming Table

- Designer Tiles Making Machine

- Everon Impex Parking Tiles Making Machine

- Tiles Making Machine

- Everon Impex Footpath Tiles Making Machine

- Concrete Mixer Machine

- Hollow Block Making Machine

- Fly Ash Brick Plant

- Hollow,solid Concrete Block Making Machine

- Muller Mixer Machine

- Concrete Block Making Machines

- Paver Block Making Machine

- Concrete Block Machine

- Paver Blocks Rubber Mould

- Paver Demoulding Machine

- Brick Cutting Machine

- Solid Block Machine

- Earth Rammer And Compactor

- Concrete Block Making Machine

- Vibration Block Making Machine

- Paver Block Making Machines

- Interlocking Block Making Machine

- Everon Impex Vibrating Table

- Sand Sieving Machine

- Interlocking Tile Making Machine

- Block Making Machine

- Contact Us

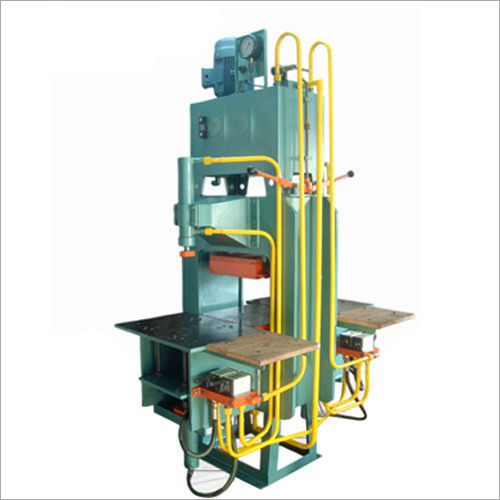

Double Punch Solid Block Making Machine

Product Details:

- Motor Power 2 HP

- Lifting Speed 12 cycles/hour

- Surface Paint Coated

- Lifting Height 600 mm

- Product Type Double Punch Solid Block Making Machine

- General Use Manufacturing solid concrete blocks

- Material Mild Steel

- Click to View more

X

Double Punch Solid Block Making Machine Price And Quantity

- 1 Unit

- 80 Liters

- Heat-treated steel

- Electric

- Stationary

- More than 8 years

- 60 KN

- Low

- 150 Bar

- 1-2 persons

- Yes

- 400mm x 200mm x 200mm

- 2

Double Punch Solid Block Making Machine Product Specifications

- Hydraulic Pressed

- 1200 blocks per day

- Semi-Automatic

- 600 mm

- Blue & Yellow

- Air Cooled

- Manual Lever Operated

- 1200 kg

- Manufacturing solid concrete blocks

- Double Punch Solid Block Making Machine

- Mild Steel

- Paint Coated

- 1800 mm x 1600 mm x 2100 mm

- No

- 440 V

- Manual / Semi-Automatic

- 2 HP

- Robust construction, high productivity, low maintenance

- 12 cycles/hour

- 80 Liters

- Heat-treated steel

- Electric

- Stationary

- More than 8 years

- 60 KN

- Low

- 150 Bar

- 1-2 persons

- Yes

- 400mm x 200mm x 200mm

- 2

Double Punch Solid Block Making Machine Trade Information

- 1 Unit Per Day

- 1 Days

Product Description

Specification

| Brick Type | Solid |

| Raw Material | Cement |

| Block Type | Solid |

| Automation Grade | Automatic |

| Usage/Application | Industrial |

| Method | Hydraulic Pressure |

| Capacity | 1000-1500 Blocks per hour |

Robust Performance and High Productivity

Designed with a sturdy frame and heat-treated steel moulds, this block making machine offers reliable performance even under demanding production schedules. The hydraulic pressing method and 150 bar working pressure ensure consistent quality and density of blocks. With a daily production capacity of up to 1200 units, manufacturers can meet large-scale requirements efficiently.

User-Friendly Operation and Low Maintenance

The machine employs a manual lever-operated control system, enabling easy handling by 1-2 operators. It features semi-automatic functionality and an air-cooled system to maintain optimal temperatures. Maintenance requirements are minimal, owing to its robust build and paint-coated surface, reducing operational downtime.

Versatile Manufacturing for Solid Concrete Blocks

This stationary machine is specifically built for manufacturing solid concrete blocks of standardized dimensions. Its versatility allows for industrial, commercial, and construction applications. The machine's blue and yellow exterior offers visibility and durability, making it a preferred choice for exporters, manufacturers, and suppliers in India.

FAQ's of Double Punch Solid Block Making Machine:

Q: How does the Double Punch Solid Block Making Machine operate?

A: The machine utilizes a hydraulic pressing method with manual lever-operated controls. It requires an electric power source and can be managed by 1-2 operators. With each stroke, it produces two solid blocks, and its semi-automatic system streamlines the block manufacturing process.Q: What block sizes and production capacity does this machine support?

A: It is designed to produce solid concrete blocks with dimensions of 400mm x 200mm x 200mm, and can generate up to 2 blocks per stroke. The daily production capacity reaches 1,200 blocks, making it suitable for high-volume manufacturing environments.Q: When is foundation required for installation?

A: A proper foundation is necessary during installation to ensure the machine's stability and optimal hydraulic performance, especially as it operates with a stationary design and delivers forces up to 60 KN.Q: Where can this machine be used effectively?

A: This block making machine is ideal for concrete block manufacturing plants, construction sites, and industrial settings where consistent quality and high output are essential. It is popularly utilized by exporters, manufacturers, and suppliers across India.Q: What is the process for manufacturing blocks with this machine?

A: Operators load concrete mix into the moulds, after which the machine's hydraulic system compresses and shapes the blocks under 150 bar pressure. Blocks are lifted to a height of 600 mm, and the process is repeated in cycles, yielding 12 cycles per hour.Q: What are the benefits of using this machine?

A: Users benefit from robust construction, high productivity, low maintenance needs, and a long service life exceeding eight years. The semi-automatic design promotes efficient operation, while its low noise level and minimal operator requirement help reduce workplace fatigue and increase productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Block Making Machine' category

|

EVERON INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |